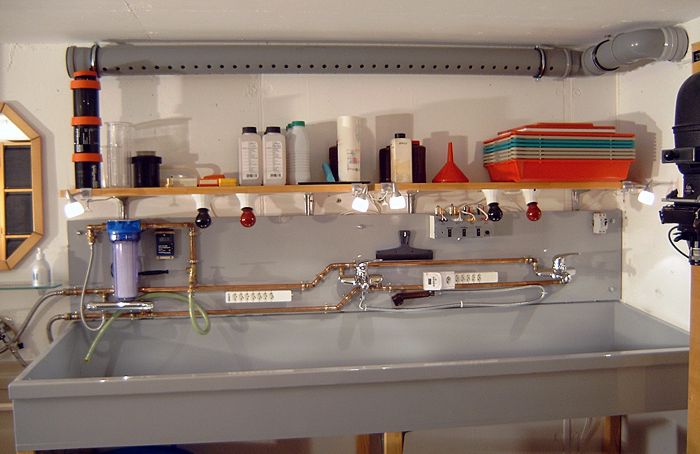

The sink right after its construction ...

Back to home page

Back to photography main page

Back to equipment page

This sink is nothing more than a large table with higher sides made waterproof.

It lets you work during a complete session and quickly clean everything at the end with a big water rinse ...

The sink right after its construction ...

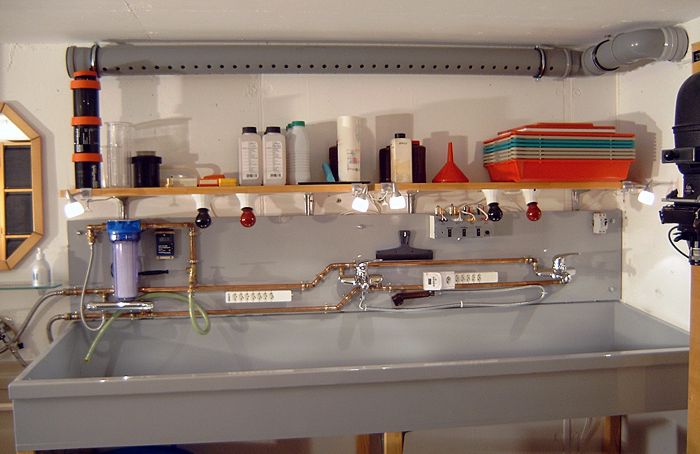

... and now with the PC screen to use the wet side section of

Dark Tools

software.

I did it with wood (MDF) impregnated with outdoor varnish and several layers of bi-component polyurethane paint normally used for garage floors.

Many other materials may be used to build sinks (fiberglass, marine varnishes, plastic panels welded together, stainless steel, ...). The result should be waterproof, chemical and scratches resistant and easy to clean.

Because of its length, around 2.50m (more than 8 feet), six feet were necessary. They are mounted on wheels to make the move of such monster easier. Mounting and painting was done close to the lab as it was impossible to move such a sink down the stairs ...

Polyurethane paint does stink, apply it in a well ventilated area.

The bottom is flat except close to the drain (left-side, not visible) where a funnel shape is used to make the drain easier. Cleaning is done with the shower and the squeegee removes all remaining water to the drain very easily.

I preferred this flat design as some processors, like my CPA-2, require to be perfectly horizontal during operation. Some prefer a small slope that allows a natural drain.

The front side, where the arms naturally rest, is enlarged for more comfort. The height of the sink is also adapted to my height.

Another more actual view.

|

The Drain.

The hole for the plug has been done before painting the sink and has been painted too to avoid water infiltrations in wood. As the bottom of the sink is pretty thick, you must find a plug longer than usual. Watertightness is achieved with silicone or special caulk for sinks. Drain tubes are made of polypropylene and can be welded together pretty easily by heating both sides of the tubes with an iron and then applying one against the other ... |